A look behind the scenes inside the water plant

Sussex Borough We make good water! was the comment from a beaming Emil Coviello, during a tour of the Sussex Borough water treatment plant on Tuesday. Coviello is the plant manager.

Mayor Jonathan Rose and Councilman Sal Lagattuta led a small contingent of media on a tour of the water treatment plant in an effort to educate the public about the plant operation and ongoing repairs. Coviello's quip came after he drank from a mug of the treated water he scooped from the 20-foot clear well. The clear well is one of the last water holding basins in the plant before the water gets pumped into the large water tank at the rear of the treatment plant property.

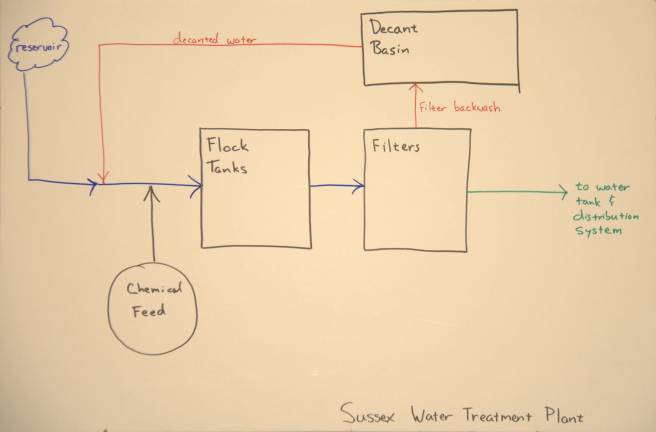

A two-hour tour The plant tour began in the six-tank chemical feed room and wound through the entire plant with its cinderblock walls lined with color coded piping and tubing, up a set of stairs to the catwalk to peer into the two floc tanks and four filter tanks, back down to the testing lab and the office where all the data from the plant operations are monitored by computer. Its a very sophisticated operation that a casual observer will not notice from the nondescript building on Route 23 a few miles outside of the borough.

The borough is in the midst of repairs at the water treatment plant ordered by the New Jersey Department of Environmental Protection (DEP). Already several of the brightly-colored chemical feed pumps have been replaced while several others are neatly stacked in boxes in the plant office awaiting installation. Repairs to the decant basin in the main room of the plant are nearing completion, according to borough clerk/administrator Mark Zschack.

One of the final items on the repair list is the replacement of the three-part media filter contained at the bottom of each of the four filters. At the base of each of the 20-foot concrete tanks are a total of three feet of media filter comprised of 18 inches of silica quartz, 12 inches of silica sand and six inches of gravel. These tree items sit atop an under-drain system that filters water to reduce sediment in the water. On occasion the system is backwashed through these same filters.

According to Coviello, the media filter lasts approximately 10 to 12 years and is slated for replacement. Mayor Rose said that original replacement estimates were about $35,000 but the contractor revised his costs to approximately $50,000 to $75,000 because the filter replacement was expected to occur one at a time and not simultaneously. Mayor Rose indicated that the boroughs qualified purchasing agent shared with Vernon is currently finalizing an agreement with a contractor to perform the work. This work is expected to begin in April and be completed in one week.

It takes approximately nine hours to complete the cycle, said Coviello. The media filter cycle includes filtering, settling, washing and decanting.

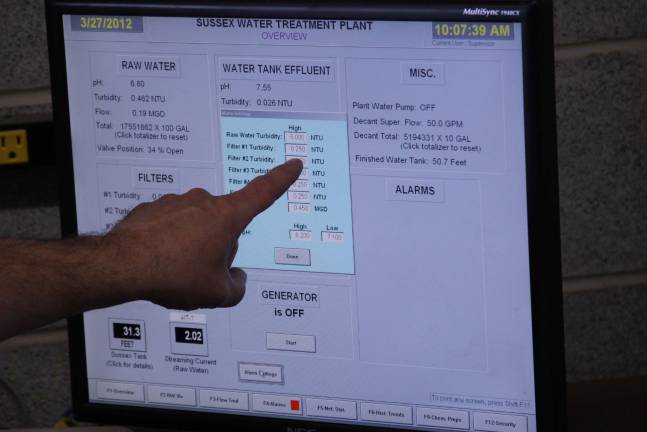

High tech plant The entire plant is controlled by computer, but can be manually operated in the case of an emergency. In fact, until recently plant procedures would call for the shutdown of the plant when there was high turbidity. (Turbidity is the cloudiness or haziness of a fluid caused by individual particles suspended solids that are generally invisible to the naked eye.) The system would then be manually shut down and backwashed to avoid excessive sediment in the system. This procedure was criticized by DEP officials last month. The borough is working with its engineers and water operator on a more efficient remedy for managing high turbidity events and improve overall water quality.

Water treatment plant maintenance could be likened to synchronized swimmers each playing an important role. All the puzzle pieces need to fit together, said Coviello. During a recent computer problem at the plant Coviello stayed on site for 30 to 40 hours straight to manually operate the system. I will not leave the facility until I am satisfied it will work properly, he said.

Mike Furrey of Agra Environmental provided a detailed explanation of the chemicals, monitoring and testing that occurs in the plant on a regular basis. He explained his role by comparing himself to a doctor. Its like writing a prescription, Furrey said. The diagnosis is high turbidity; you need to add just the right chemicals. Furrey proudly displayed the lab with its wall mounted monitoring devices and bench test area where the water system components simulate the plant but at a much smaller scale. Agra Environmental is the independent testing company retained by Whitewater, Inc., the operator of the plant. Coviello is employed by Whitewater.

The Sussex Borough water treatment plant treats approximately 200,000 to 300,000 gallons of surface water each day. The plant is rated for 600,000 gallons but is capable by DEP permitted to treat one million gallons a day. Mayor Rose indicated that the plant currently operates at 50 percent capacity. Another 500,000 gallons of water is stored in the water tank located in the borough.